A common misconception in manufacturing is that only those manufacturers that use high-speed cutting in their processes benefit from tool balancing. The reality, however, is that any manufacturer can stand to benefit from the increased productivity, added precision, and better surface finishes that a balanced tool can provide.

Too often though, manufacturers fail to or are reluctant to balance tool assemblies. This can lead to concentricity errors and tools with uneven weight distributions that can cause excessive vibration in the spindle and workpiece during machining. This not only harms surface finishes on parts and severely reduces tool life, but also negatively impacts a manufacturer’s bottom line. This article will explain the importance of balanced tool assemblies and explain the steps that manufacturers can take.

Why do you need a balanced tool assembly?

Tool assemblies consist of two main components: the tool holder that’s fitted into the machine and the cutting tool that fits into the tool holder. Manufacturers need to balance both these components to avoid unwanted chatter during machining. Too much chatter can lead to poor surface finishes on parts, but also an inability to hold tight tolerances, significantly reduced tool life, and consequently, diminished productivity and profits. Running jobs while using unbalanced tools can significantly damage machine spindles – repairs of which can be upwards of thousands of pounds. With balanced assemblies, these problems can become a thing of the past.

Many manufacturers are reluctant to balance their tool assemblies because of:

- The associated increased costs of adding extra processes

- The additional cost of purchasing a tool-balancing machine

- The perception that their operations don’t warrant the need for balanced tool assemblies.

However, many manufacturers have achieved increased productivity due to the reduced machine wear and improved quality that this method provides. Less chatter equates to less tool breakage and wear, improved part quality, and improved cycle times.

Balancing act

It’s important to keep in mind that when an entire tool assembly is located in the machine’s spindle, it must be balanced to ISO 1940-1 rating (such as G2.5 or G6.3) depending on the maximum allowable spindle revolutions. More often than not, the tool holder and cutting tool that comprise the complete tool assembly are made by different manufacturers. As a result, shops try to balance each component individually for jobs, but a better practice is to consider the entire assembly.

For machine operators, this means being aware of the balance rating for both the tool holder and the cutting tool. Many CNC machine manufacturers now include balance rating plaques on their machines to clearly show suitable ranges for G-ratings of their spindles. In the case of spindle failure, if these ratings are not followed, the machine manufacturer may void warranties and refuse to complete repairs, as the spindle has been running outside of the recommended parameters.

Three methods of tool balancing

Balancing tools allows manufacturers the opportunity to improve part quality and increase productivity but can be challenging if a single tool holder is used for multiple tools. Here are three methods for tool assembly that manufacturers can implement:

1. Add weight

While many tool holders are advertised and sold as ‘pre-balanced,’ a good rule of thumb to follow is to always balance tools anyway. One way manufacturers can do this is to add weight to them by attaching weighted set screws, rings, or small counterweights. These added weights can be modified or removed should the tool holder be used for a different cutting tool.

Knowing how much weight to add, and where, can be tricky though. This is where using a tool balancer comes into play. Tool balancers measure unbalance by rotating a tool assembly and measuring the developed centrifugal forces. From there, the machine converts the results into a tangible number showing the degree of unbalance and corrective actions that must be taken.

2. Remove weight

Balance can also be achieved by removing weight from tool holders by way of an array of drilled holes or milled flats.

3. Shift the weight

Shifting the weight on a tool assembly, whether through the use of counterweights, balancing rings, or set screws is another way to balance tools.

Types of tool holders

With all the different types of tool holders on the market, it can be difficult for manufacturers to pick the right one for their application. Different types of tool holders include:

- Sidelock holders

- Collet chucks

- Hydraulic chucks

- Shrink fit

The most commonly used type for balancing tools is shrink fit holders. These holders do not have any moving parts, which means that there is less chance of weight being distributed unevenly. Sidelock holders, on the other hand, are less likely to be balanced due to the presence of screws needed for clamping. For these holders, tool balancing must be completed to correctly redistribute weight.

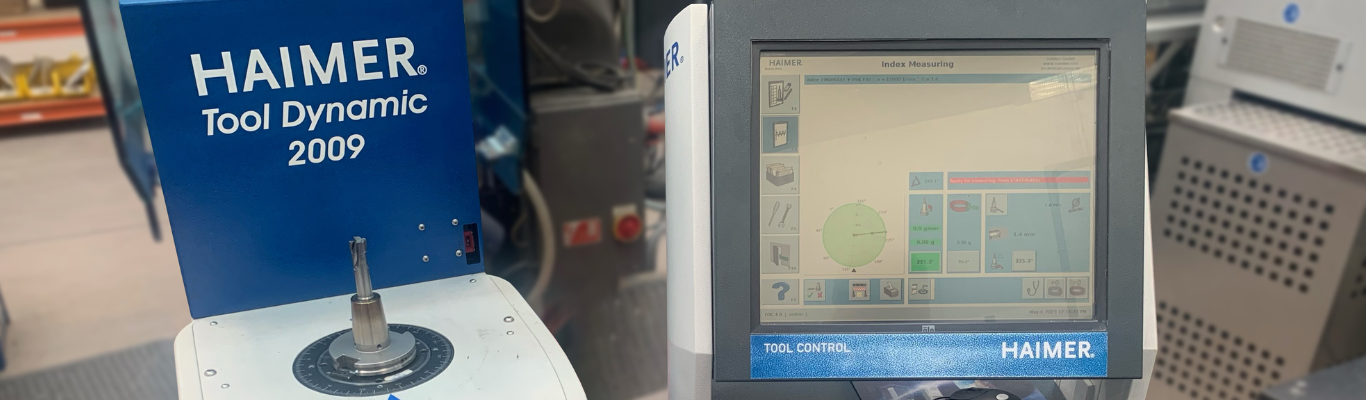

Introducing an inherently unbalanced cutting tool into the equation can affect the entire assembly. This is where using a tool balancing machine could be beneficial. These machines can measure the degree of balance in an assembly and prescribe the necessary corrective actions.

Balanced tool assemblies run better

Whether a PCD tool using high spindle revolutions, or an HSS is used, all machining processes stand to benefit from balanced tools. With this method, manufacturers can realise improved quality with increased efficiency and productivity. Here at Exactaform, our experience with custom cutting tools is unmatched. We regularly assemble tools for our customers using a Haimer tool balancing machine to measure and correct balance before delivering our products to customers. Contact an Exactaform sales representative today to discuss your custom cutting tool needs.