Exactaform’s precision-engineered PCD tooling solutions offer high wear resistance, extended tool life, and exceptional performance for aerospace, automotive, and high-volume manufacturing applications.

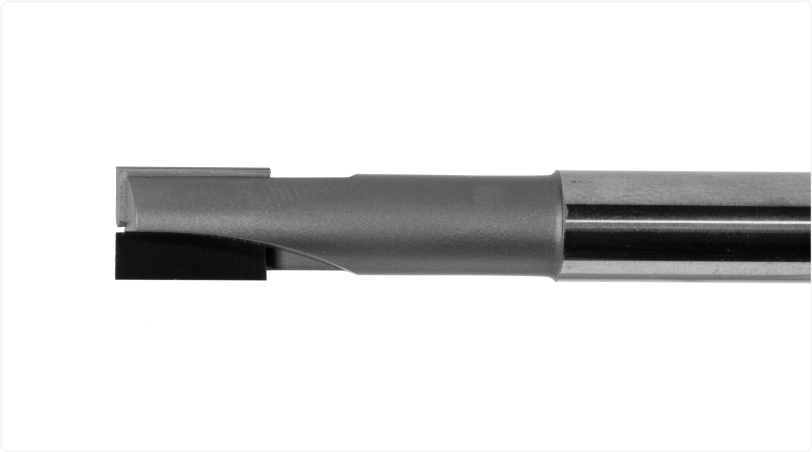

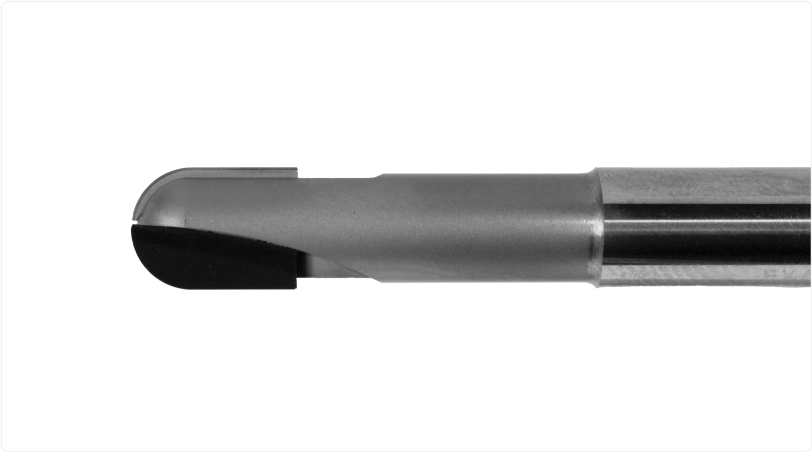

PCD tools are exceptionally robust and resilient composite cutting tools. They’re created by mixing small diamond particles with a binder (usually metallic) under intense conditions, namely pressure and temperature. This occurs in a high-temperature-high-pressure (HT-HP) press. The spaces between the diamond crystals are filled with a cobalt alloy.

The result is tools with exceptional cutting edges that are prized for their hardness. Being made from diamonds, engineers employ these tools in harsh machining situations that test a tool’s toughness, wear resistance, and ability to dissipate heat.

PCD tooling can be used to cut many materials, especially abrasive materials like carbon fibre or fibreglass, which would quickly wear out carbide tools.

PCD cutting tools are not suited to cutting ferrous metals because of the reaction between the carbon atoms in the diamond and iron particles that form iron carbide, breaking down the diamond structure.

PCD diamond tooling forms the backbone of many automotive and aerospace manufacturing processes. PCD tools cut tough aluminium alloys, ceramics, and carbon fibre at high speeds, and their tough cutting edges mean the tools can be in service for longer before replacement. They excel in high-volume processes that demand razor-thin tolerances.

Exactaform are one of the UK’s leading manufacturers of custom PCD tooling; get in touch today if you’d like to learn more about our custom solutions.

With their high wear resistance, PCD tools can be used for longer. Depending on the product being cut, PCD tipped tools can outlast carbide tools by a significant amount of time. This makes PCD tools an excellent choice for high-yield production facilities.

PCD tools can reduce lead times and increase machining capacity as they can be run up to 10 times faster than carbide tools at their peak efficiency. This means that more work can be completed without the need for additional machines or personnel.

PCD tools retain a sharp cutting edge for longer. This may negate the need for secondary finishing processes like grinding as high-quality surface finishes can be maintained.

PCD tools refer to Polycrystalline Diamond tools, which are cutting tools used in machining.

Because PCD tools retain their sharp cutting edge for longer, tighter tolerances can be maintained over a longer period of time. This results in machining processes capable of maintaining machining tolerances for longer, potentially reducing inspection frequencies.

PCD tools can be resharpened, however, the higher wear resistance of PCD tools means less-frequent resharpening, resulting in reduced downtime.

The initial, upfront cost of a PCD tool may be 2-3 times as much as that of other solutions. However, longer tool life, reduced downtime, and reduced processing time mean its ongoing pound-per-linear foot machining cost is up to 80% less, resulting in long-term cost savings.