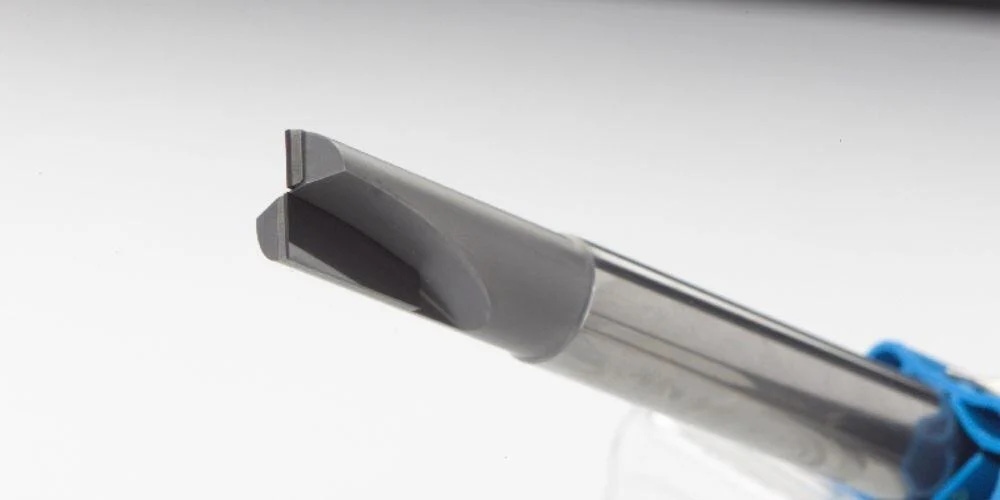

eco-cut is a PCD tool range created for the needs of model board, graphite, plastic, aluminium and composite machining. These materials require tools that can withstand abrasive surfaces without the need for extreme durability suited for highly abrasive metals. With eco-cut, you get tools that offer the durability and efficiency of PCD at a cost suited to applications that benefit from wear resistance, reliability, and affordability. Discover how eco-cut can streamline your machining processes, reduce downtime, and maintain consistent performance.

eco-cut is our affordable PCD tool range designed for model board, graphite, plastic, aluminium and composite machining. These tools are designed to provide long-lasting wear resistance without the high cost of our highest quality PCD tools, making them a smart choice for applications that prioritise cost-effectiveness without sacrificing reliability. eco-cut is manufactured with Exactaform's PCD expertise, providing a solution that fits the budget and performance needs of businesses working with softer, abrasive materials.

Suitable for a variety of milling purposes, from initial roughing to detailed finishing.

Precise, clean cuts for creating slots or grooves in modelboard.

Accurate profiling for detailed shapes and contours, allowing for custom designs.

Ideal for creating bevelled edges, adding precision and detail.

Achieves smooth surface finishes for high-quality prototypes and models.

Maintains accuracy in complex model board designs, reducing the need for secondary operations.

eco-cut is ideal for businesses that need dependable performance in model board, graphite, plastic, aluminium and composite machining across a range of industries.

It’s a perfect choice for those in sectors like:

Perfect for creating accurate prototypes with model board and plastic materials

Ideal for machining plastics and model boards in production applications.

Suitable for companies that require durable tools for shaping model board or similar materials.

Where aluminium and composites are often used for their strength-to-weight ratio

Fill out the contact form below, and one of our team members will get back to you to discuss how eco-cut can enhance your modelboard machining processes.