A wearable system that helps organisations understand, manage, and control hand–arm vibration exposure in real working environments.

The HAV-Sentry System is a wearable vibration exposure monitoring system designed to help organisations prevent Hand–Arm Vibration Syndrome (HAVS), improve safety and wellbeing, and meet their obligations under the Control of Vibration at Work Regulations.

Supplied by Exactaform, HAV Sentry replaces manual estimates with real-time data, giving employers clear visibility of hand-arm vibration exposure as it happens across demanding work environments.

Hand–Arm Vibration Syndrome (HAVS) is a serious, permanent occupational condition caused by prolonged exposure to vibration from vibrating tools, power tools, and heavy machinery.

Across the United Kingdom, more than two million workers are estimated to be at risk. In sectors such as manufacturing, assembly, construction environments, and wider industrial operations, repeated vibration exposure is often unavoidable without effective controls.

Common symptoms include:

Once established, HAVS is irreversible, making prevention, early detection, and accurate vibration exposure monitoring essential.

It’s a remarkably costly one which can have devastating impacts on your business, too.

The average Health and Safety Executive (HSE)-inforced penalty for confirmed HAVS cases amounts to £250,000, but it can be upwards of £500,000.

Companies also face the responsibility of compensating affected employees, too an average of £18,000 per year for the duration of the employee’s career.

Aside from the significant fines, the HSE also has the authority to name companies with confirmed HAVS cases publicly.

This can have a catastrophic impact on your ability to employ future talent, retain your current workforce, and gain access to Government-funded workplace schemes and grants.

Worst of all, an employee’s quality of life has worsened because their employer did not have the right preventative measures in place.

The penalty and compensation costs, albeit high, can be recouped. However, once an employee has HAVS, they have it for life.

Under the Control of Vibration at Work Regulations and associated British Standards, employers must:

Guidance from the Health and Safety Executive makes clear that employers must be able to demonstrate how vibration exposure is measured, controlled, and reviewed. HAV Sentry is designed to support this requirement with defensible, real-world vibration measurement technology.

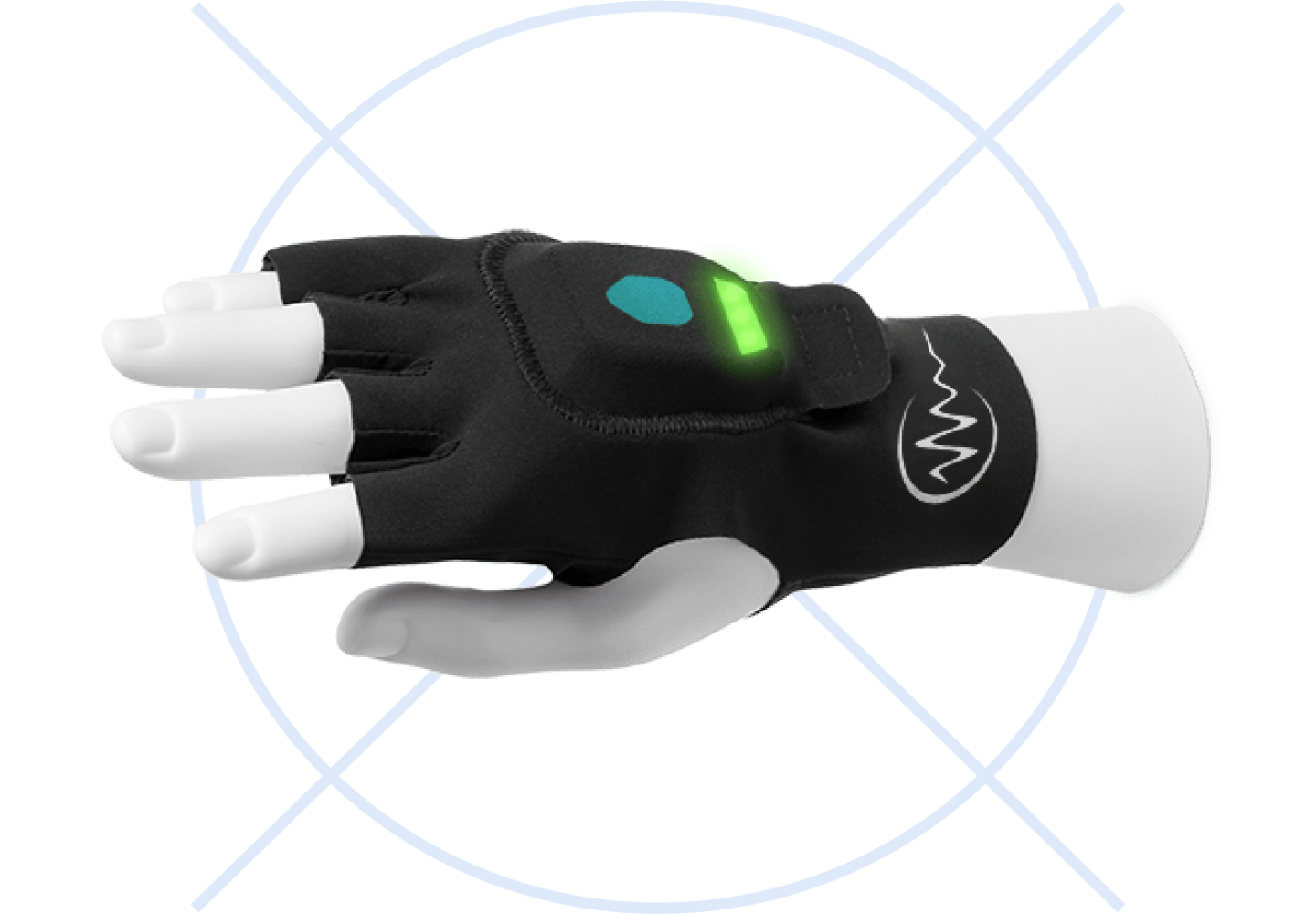

The HAV Sentry Glove integrates advanced wearable tech with purpose-built measurement devices designed for real industrial use.

Aegis sensing units embedded within the glove capture vibration directly from the wearer’s palm, ensuring accurate measurement at the true exposure point.

This approach delivers:

HAV Sentry is a wearable monitoring solution that continuously measures hand-arm vibration exposure at the point of contact.

Using advanced measurement technology and vibration technology, the system captures actual exposure during real work activities rather than relying on manufacturer data or manual vibration log-books.

Key capabilities include:

This enables earlier intervention, before exposure becomes harmful.

Aegis sensing units within the HAV Sentry wearable measure vibration exposure continuously and in real time.

The system:

If exposure approaches unsafe levels, the wearer receives immediate visual and audible alerts, enabling corrective action before limits are exceeded. This proactive approach reduces unnoticed overexposure and supports safer decision-making on site.

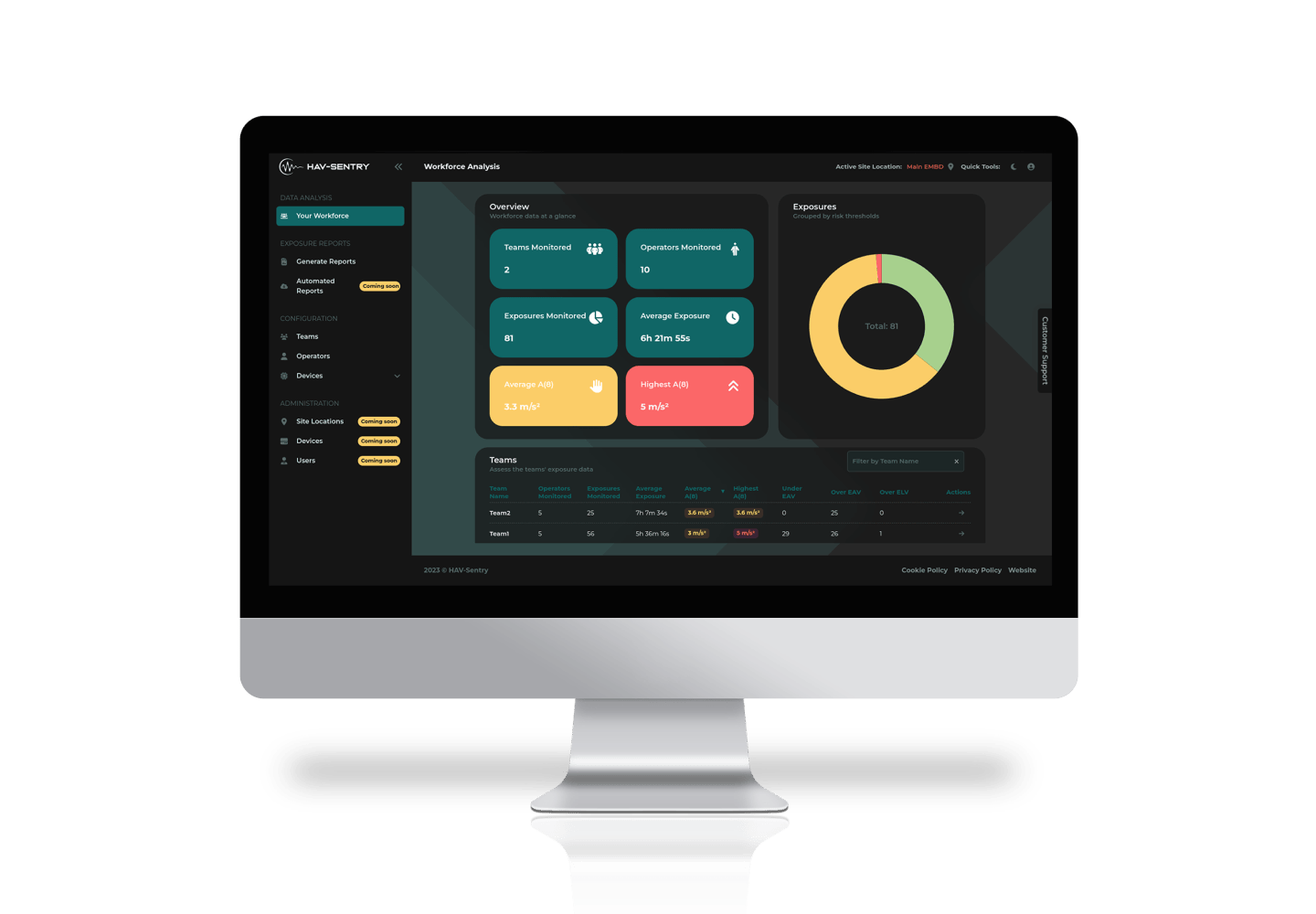

All vibration data is securely transmitted to the HAV-Sentry Dashboard, a cloud-based monitoring and analytics platform accessible to safety practitioners, compliance teams, and operational managers.

The dashboard provides:

Hosted on Amazon Web Services, the system supports secure digital safety management and modern safety technologies.

HAV Sentry is built for daily use in demanding conditions involving heavy machinery, vibrating tools, and variable environments.

This ensures monitoring devices remain practical, reliable, and unobtrusive.

HAV Sentry helps organisations:

It is not just a monitoring tool, it is a HAVS prevention and Risk Management system designed for modern occupational safety.

Exactaform can help. Our expert team are ready for your enquiry.